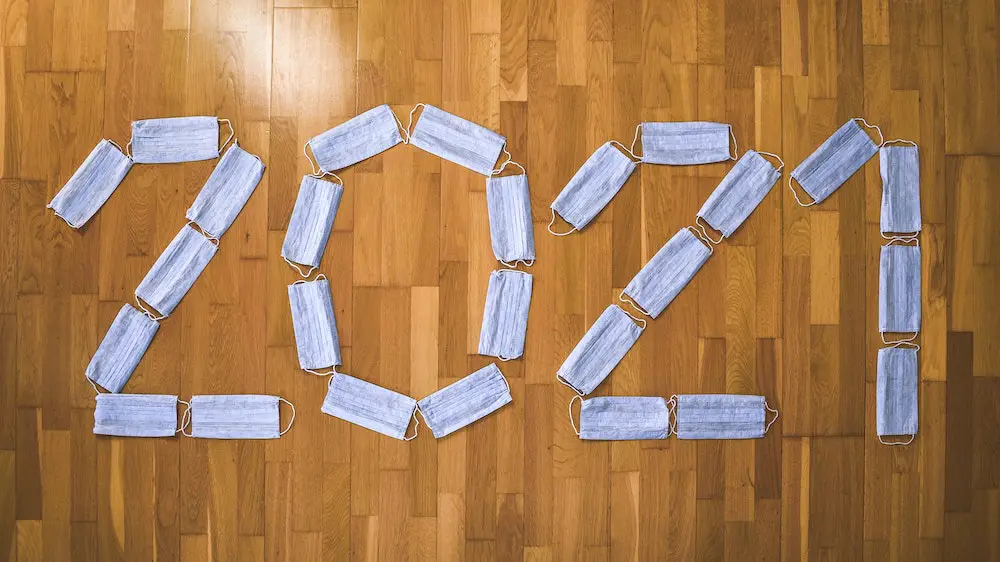

Quite a few companies have been forced into recession since the first wave of the pandemic. 2021 will also be an extreme endurance test for the industry. But has the coronavirus infected Germany’s most important industry, metal, and thus the heat treatment industry?[nbsp]

Extreme dependencies on the automotive industry are showing their fatal consequences during the pandemic. So far, however, the strongest effects could only be assigned to the first corona wave. Since then, an entire branch of industry has been converting and finding new ways and means to come to terms with the current market conditions. So far, many companies have not been able to return to the pre-crisis level – an aftereffect that is currently producing little information.

Operational Impact

Around 80 percent of the companies are affected by production restrictions and a significant increase in short-time work is shaping the situation. If you sketch the figures, many companies have their backs to the wall. A lack of demand is the main reason for lower performance capacities, especially since the automotive sector is weakening dramatically in its sales figures.

Due to the improved framework conditions for short-time work, around half of all companies are still not facing a wave of layoffs. Employees currently have to make ends meet with an average of 44 percent less working time. Without a doubt, the possibility of flexible working hours is the most important support tool for companies and employees to date and offers one of the most effective perspectives. Because: If the demand increases, the working hours can immediately be extended step by step.

New structures in process chains[nbsp]

After significant tightening, bottlenecks and total production failures, the year 2021 is likely to be an extreme endurance test. The upstream investment behavior changes due to the indirect effect of consumer behavior on the industrial sector. Missing parts from suppliers within complicated manufacturing chains are only one factor of the problem. Much more serious in this situation are poorly evaluated or too old structural deficits.[nbsp]

A logical consequence: In addition to all other branches of industry, the heat treatment sector is also looking for solutions. More robust processes are one of them, more digitization is the other. These past failures have a negative impact. At least for a while. It can be seen that most companies are looking for significantly more digitization solutions in order to better coordinate their processes and be able to act in a more time-saving manner. In the competition for the hitherto financially strong automotive industry, innovative approaches are required – and now the right phase of transition seems to be the right transition for many companies.

Another sticking point in the system’s vulnerability: international suppliers. The dependency on Asian markets has never been as evident within a few weeks as in the corona pandemic. A problem that all of Europe must now face.

Even from the Middle Kingdom, hardly any more positive figures came to the public in 2020. Sales slump of up to 80 percent in February 2020 compared to the previous year and 42 percent in the entire first quarter of 2020 – a pure disaster for performance-oriented China. However, the close connections between functioning production chains in Europe and the delivery of individual modules from Asia, as well as the sale of any products in the Far East, are worrying. Current bright spot: due to the official end of the corona crisis by decree of the Chinese government, the numbers in China are picking up again; which the German industrial companies are also feeling again. The dependency, however, remains.

No chance for specialist exhibitions

Pandemic effects are not only evident in production, but also in the initiation of business. Specialist exhibitions have been postponed or canceled entirely, and business trips have been reduced to an absolute minimum. Only those who absolutely have to be on site to maintain the processes are received. Sales pitches are shifting to video conferencing; the acquisition of new customers has almost come to a standstill. But production downtimes and delay decisions on important industrial equipment issues add to the confusion. Due to the precarious situation, companies invest primarily in hygiene measures. Companies that already planned new solutions during the first lockdown phase and implemented them in a few months will now experience a small competitive advantage as the pandemic progresses.

In fact, hardening shops are currently experiencing a total restructuring of business processes. Empty ovens and systems must be operated well beyond the scheduled maintenance intervals. Industry service providers should process the few existing orders within the shortest possible time. On the one hand, increased stocks are cost-intensive for companies, but on the other hand the industry needs suppliers who can deliver quickly, if possible from stock, in order to keep the companies running. A dilemma!

Potential through the crisis

It remains to be seen whether a digitization surge triggered by the corona pandemic can be demonstrated in the heat treatment industry in the near future. What is certain is that production had to accept losses and is now trying to compensate for these more homogeneously using more efficient processing and manufacturing methods.

The causal connection between Corona-related measures, production losses, short-time work and international delivery dependencies is documented: Such a global crisis situation can also result in opportunities. Especially for all those companies in the heat treatment industry who are ready to question the processes and costs of their own productivity. Companies also need to rethink their role in the market. Your own focus should be based on your individual strengths, instead of trying to establish yourself in every product area. A return to the actual preferences and a resulting change can already be seen in a direct comparison to 2020. While the first lockdown was largely accompanied by a total collapse in production, a significantly larger number of companies will master the corona difficulties in 2021.

Corporations tended to use the short-time working model more often than the average, while domestic suppliers immediately tried to find a customer-specific niche and meet complex order requirements.[nbsp]

Specialized hardening shops are concentrating on a stronger expansion of digital system technology in order to be an important step ahead of the slow development towards normality. In other crises, international trade relationships and exports have been the saving anchor for various industries.

Recovery through economic stimulus programs?[nbsp]

The effects on the heat treatment sector underline the complex interrelationships of entire industries and once again illustrate the fragile foundation of the economy. Similar to the financial crisis of 2008/09, committed companies are using the crisis to gain important experience and to restructure and position themselves better. Car rewards are one way of stimulating consumers and thus the economy. But bonuses are certainly not the bringer of salvation; the true redemption in all corona questions clearly points to a medical solution – and that is not at the discretion of the heat treatment industry.

Let’s stay in touch!

The corona pandemic shows us once again how important mutual exchange is. We can only cope with this difficult time together, so I would like to invite you to a lively exchange:

- What are the specific effects of the pandemic on your company / your workplace?

- What developments do you see in the heat treatment industry as a result of the pandemic?

- What role does the current situation play with regard to our following topic “The development for the industry away from the internal combustion engine” (see also our blog post ” Banishment of internal combustion engines ” from September 2017)?

Use the comment function on our blog and exchange ideas with us!

[nbsp]

[nbsp]

Sources:

https://www.destatis.de/

Recent Comments