One of the most important industries in Germany has got into a massive crisis as a result of the pandemic and the effects of COVID-19. Loss of sales and drastic declines in production dominate everyday life. This additional and completely surprising change in the market affects manufacturers and suppliers in the middle of an already painful restructuring phase. A phase in which the entire heat treatment industry has to adjust to electromobility.

Electromobility in the EU

The developments in recent years due to innovations in electromobility show clear trends. Germany and other European countries agree on phasing out fossil combustion engines. The only variable: the remaining time. While Audi has announced that it will not phase out internal combustion engine production until 2035 in order to become climate-neutral, Norway intends to take this step by 2025.

The worldwide entry into the exit

General Motors will do it in 2035, Toyota only in 2050 and Volvo is heading for a completely new design and sales concept as early as 2030. We are talking about phasing out incineration technology. VW, Daimler, BMW are increasingly focusing on a clearly defined exit scenario. Some others shy away from a fixed announcement, but car models with diesel or gasoline engines are already part of the future past. General Motors surprised with the statement that from 2035 onwards only emission-free vehicles would be produced in order to become CO2-neutral overall. For the industry (and especially for the displacement-loving Americans) a radical step that Volvo was able to beat. The Swedes are renewing their sales network from 2025 and only sell electric models. Thus, Volvo is the official first-time dropout.

Anyone who wants to survive on the market has always had to adapt to new requirements – even better: adapt quickly ! Are the German flagships, which have become relatively thick in the last few decades, not only able to constantly develop new model variations from the same construction kits, but also completely new technologies? Can we also “think outside the box” or just “okay; do we also take part ”?

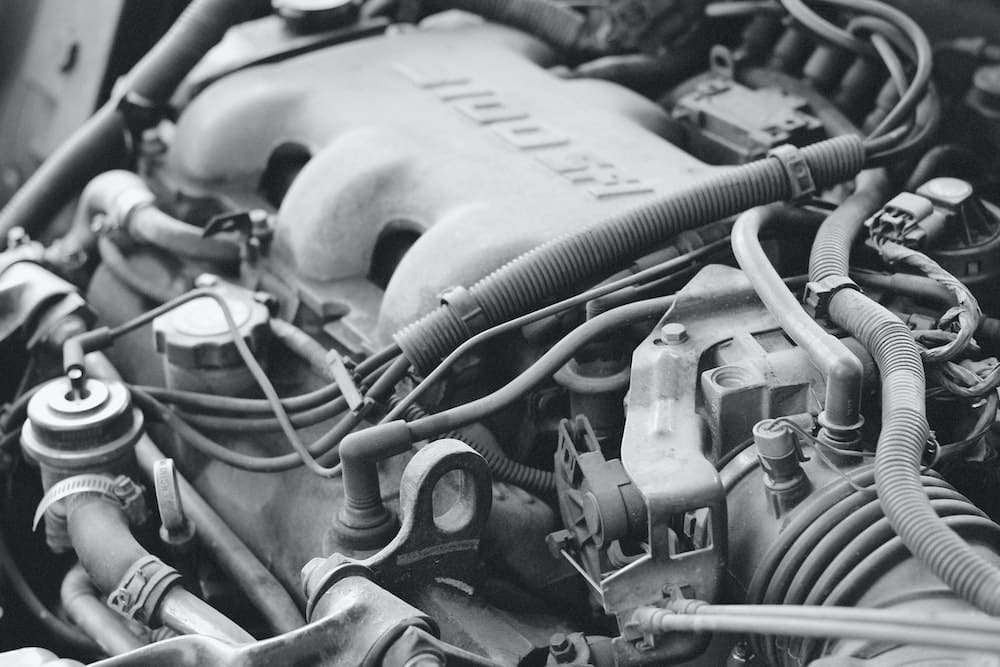

A lot has happened since our blog article ” Banishing Combustion Engines ” in 2017! The fact is still: In total, electric cars have fewer hardened components than conventional vehicle designs. In 2017 we established an exit scenario by 2030. In fact, the deadline for exclusively emission-free car registrations looks different today. Norway is setting an example by 2025, followed by Sweden, Denmark, the Netherlands, Ireland, Slovenia and Iceland by 2030 and Spain and France by 2040. The most important vehicle markets with China, the USA and Brazil have not yet published any fixed exit targets. Germany will join this development by 2035. As the development progresses, these periods of time will rather shorten than lengthen.

New opportunities for industry

Approval forecasts for 2021 assign more than 20 percent of all new registrations to electric-powered mobility and hybrid motors. However, since the design of electronic vehicles has hardly changed in recent years, the focus in technological advancement is on innovative battery technology. Apple in particular is currently drawing attention to itself with reports in this regard. The group wants to be present on the market with a revolutionary battery technology as early as 2024. According to rumors, the company has been working on its own self-driving car since 2015. Thanks to the raw material lithium iron phosphate, the range should be much greater than was the case with previous models. Changing the structure of the battery not only saves space, but a higher charge density will probably make the breakthrough of the Apple battery possible. But the American technology giant is not satisfied with a modern battery concept alone. Apple is working on a strategic realignment and developed a self-driving system behind the scenes. Quite an interesting technology with LIDAR sensors for spatial detection. Tesla’s reaction to this new development will be interesting, especially with regard to the new plant in Brandenburg. Is that the new trend in high-tech? Development is carried out overseas and Germany only serves as an extended workbench? Volkswagen wants to at least stay on par, but it is doubtful that after a delayed starting grid there is enough power on the battery to be able to overtake the innovative giant.

The development itself is being watched with caution in the heat treatment industry. If companies like Apple achieve a breakthrough with this completely new battery design, steadily declining sales figures will be sealed for the heat treatment industry. Since less hardened parts are built into an electric car, a triumphant advance of this type of vehicle will increasingly force hardening shops to rethink. Hardened components such as shafts or planetary gear sets are also built into electric cars and the demand for components and spare parts for combustion engines and hybrid vehicles that have to be hardened will not suddenly disappear – but the market will continue to shrink.

Due to the planned CO2 regulations of the European Union, newly registered cars will have to emit around 55 percent less CO2 in just under 10 years than was the case in the whole of 2021. Classic combustion engines and almost civil engineers cannot keep up with this CO2 regulation. For this reason, the EU’s concern is to be seen as a “de facto ban” for internal combustion engines. The domestic industry will probably have to comply with the regulations in the next 10 to 15 years, so that from 2035 onwards no new diesel or gasoline engines will be sold in this country. It seems that after years of reluctance and rebellion against these regulations, German industry is now comfortable with putting its own solutions on the table that can do without a “calibration factor”.

Are the forecast values from 2017 realistic?

The forecasts from our blog article “Banishment of Internal Combustion Engines” (2017) can only be used to a limited extent for confirmation / falsification. The reason can be found in the corona pandemic and the resulting collapse in the automotive market. New registrations and sales figures have fallen to a minimum.

In 2017, we predicted growth in worldwide new registrations (2015 to 2020) of 18.6 percent. In fact, the market is down 12.2 percent over this period. The reasons for this lie in the effects of the corona pandemic on the automotive industry. However, even when looking at new vehicle registrations around the world until immediately before the crisis, according to Scotiabank’s figures, growth of only 3.1 percent (2015 – 2019) was achieved. Thus, the market has grown, but not to the extent forecast in 2017.

| [nbsp] | Forecasts 2020 | Status 2019 * |

| Growth worldwide new registrations | 18,6 % | 3,1 % |

| Share of electric cars | 2 % | 4 % |

* Since the values from 2020 are not reliable.

Electric cars, on the other hand, exceeded the forecast values. For 2020, a share of vehicles powered by electric motors of 2 percent of new registrations worldwide was predicted. However, as early as 2019, the ADAC reported that electric cars account for 4 percent of new registrations. These figures illustrate the rapid development and strong dynamism of the market.

Importance for the heat treatment industry

For the first time in history, car manufacturers were confronted with an almost complete halt to their supply and production chains. Large stockpiles of vehicles and hardly any sales already presented the industry with an enormous challenge.

The pandemic then does the rest, as the failure of supply chains brutally reveals the weaknesses of just-in-time piety. As a subsequent reaction, the entire heat treatment industry had to undergo an abrupt structural change in order not to come under even more pressure. The electric motor will gain acceptance, but it is not entirely clear whether the hydrogen mobile favored by experts can deliver a significantly better performance over time. The next few years will tell. Of course, also taking refined technology into account. As in 2017, the changes can be planned, panic is unfounded. Combustion engines will not be pushed out of the market overnight, nor will hardened car components come to an unforeseen end.

One thing is certain, however: the demand for heat-treated components for the automotive industry will continue to decline. Therefore, the appeal remains similar to 2017 – the current economic situation is not an invitation to rest. Especially in pandemic times, the industry should prepare for the restructuring in order to be able to benefit from innovative technologies and industry in the future.

- How do you see the current development?

- Do you think the corona pandemic may have bought the heat treatment industry a little more time?

We look forward to your opinion!

Recent Comments